Formulation advantages of transparent oil thickening

A new solution to naturally modify the rheology of cold-processed oil-gels

Kristin Köhler, Sabrina Paltian – Berg+Schmidt

Abstract

Time dedicated to new formulation development is getting shorter and shorter which is why formulators are constantly looking for new solutions making their lives easier i.e. easy to add-in ingredients which do not require too long process time. When it comes to transparent oil gels, viscosity and flow behavior play and important role for the well-being of the consumer while applying the product. There are existing ingredients like polymers or organoclays which still leave some space for improvement. This article deals with a new ingredient solution for natural and globally approved oil gels, transforming textures and new playful concepts.

Introduction

As with most cosmetic products, the actual value is determined by consumer expectation and perception of the formulation. Once applied, the product is assessed for its sensory properties and general application behavior. Especially when it comes to oils and other liquid, anhydrous systems, it happens that the product itself is too runny, evaporates too quickly or does not remain at the targeted skin area e.g., active loaded facial oils. Besides, formulations with an optimized and modified texture will be perceived as more caring and luxurious, hence further increasing the products value. Other beauty rituals and routines like Ayurveda treatments are becoming more and more popular. Here, a longer spreading time of e.g., jellified massage products will help to prolong the impression of wellbeing. There are many more reasons why jellified oils are a desirable format for care concepts. To the formulator, however, it is most important to find suitable functional ingredients to achieve stable and ideally transparent systems without losing resources on process time and energy costs.

Choosing the right thickening system

Different systems to solidify oils exist on the market i.e. zinc or aluminum stearates, silicium dioxide or organo-clays. Most of them have a limited solubility, form three-dimensional network structures, and show an interparticle interaction. Further, fatty acids, waxes or polymers can be used for the purpose of oil thickening. However, not all of them work in the same way and are suitable choices for pure and transparent oil gels. The different options can be distinguished by their origin and behavior i.e. formation of stabilizing and thickening structures. Organo-clays like hectorite and bentonite belong to the class of layered silicate. They form crystal structure consisting of many layers and which can store oil in between these layers. This creates three-dimensional network structures that increase the viscosity of the oil. The texture from the pure oil changes from liquid to paste or solid.[1] [2]

In contrast to that, polymers are long-chain macromolecules consisting of repeating monomers.[3] They creates a three-dimensional network with its long chains. Here, the oil is enclosed like a scaffold. Silica itself forms stable and transparent oil gels. However, the sensory often does not comply with consumer requirements.

Natural blend for oil thickening in cold process

Besides the commonly known options previously described, formulators have further choices of blended products containing natural polymers based on castor oil. The combination of olive squalane, hydrogenated ethylhexyl olivate and the copolymer of hydrogenated castor oil with sebacic acid (e.g. BergaCare FG Gel) has shown to be very suitable for use in cosmetic formulations i.e. from anhydrous oil gels to cleansing milks and lip products. It is a blend made of natural emollients, a texturizer and stability enhancer with film forming and viscosity enhancing properties. This blend (INCI: Hydrogenated Ethylhexyl Olivate, Hydrogenated Castor Oil/Sebacic acid Copolymer, Hydrogenated Olive Oil Unsaponifiables) comes as a transparent pale yellowish gel which is, in contrast to other ingredients, cold-processible in pure oil and requires adequate shearing force by using rotor-stator or propeller stirring device. The device used has no influence on the final texture or viscosity. When tested in pure sunflower oil, the thickening blend has shown to build up its final viscosity after 24 h at RT leading to a jelly-like appearance. The final viscosity depends on the use concentration and oil used. Thanks to its natural thixotropic behavior it liquefies again once shaken or stirred. This rheological appearance makes it ideal for spray or pump packaging.

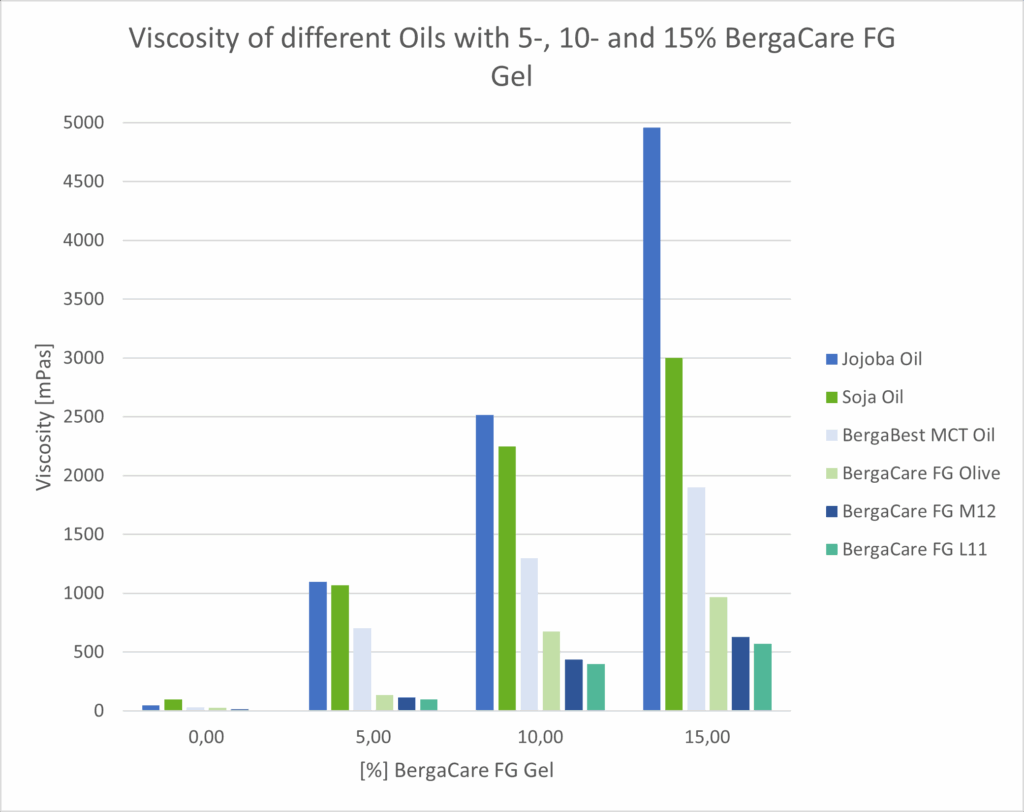

Fig. 1. Different oil types thickened at different use concentrations of rheology modifier blend compared to the pure oil.

Compatibility with different oil types

As shown in figure 1, vegetable oils and natural esters are extremely suitable for pure oil thickening. Furthermore, not only the viscosity, but also the texture changes which may lead to a completely different perception of the oil once applied to the skin. Jojoba oil for example shows a significant increase in viscosity turning into a pleasant gel. Other vegetable oils like olive or sesame become more jelly-like. In contrast to that, mixed and modified castor oil shows a honey-like texture. The natural oil thickening blend is not only compatible with various oil types, but also allows for different textures and concepts as further shown below.

Formulating commonly used ingredients

Especially for physical UV filters the products aesthetics play an important role. Facial fluids or other usually liquid sunscreen formulations based on fast spreading emollients risk to be too runny. A simple sunflower oil base thickening with the blend has shown to become a stable oil gel when loaded with Titanium Dioxide or Zinc Oxide. Hence, one solution for a better on-point application of important sun care products. Other solid particle like pigments can be incorporated into a cold-processed oil gel making the thickener a good choice for color cosmetics. Water or hydrophilic active ingredients can be incorporated by up to 5% leading to some turbidity due to the refraction. However, slightly decreasing the amount of oil may bring cost advantages.

Oil rheology modifier in emulsion products

Formulators and consumers alike know how important sensory is with skin care products. As mentioned above, the mode of application is important but also other sensory parameters are key i.e. the body of a product. With the term “body” we describe the amount of product which remains between the fingers after dipping into the jar forming a cushion. The below shown o/w emulsion has been formulated with 3% hydrogenated lecithin as natural standalone emulsifier as well as 3% of the thickening agent in a total oil phase of around 28%. Here, the adding of the thickener is responsible for jellifying the oil phase and providing body to the whole formulation. Further sensory aspects like the skin after feel are enhanced e.g. rich, but non-tacky.

| Phase | Product | INCI Name | Supplier | % (w/w) |

| A | Demin.Water | Aqua | diverse | 57.1 |

| A | Glycerin | Glycerin | Berg+Schmidt | 4.0 |

| A | BergaSom Sun 75H | Hydrogenated Lecithin | Berg+Schmidt | 3.0 |

| A | Cosphaderm Pentiol Natural | Pentylene Glycol | Cosphatec | 5.0 |

| B | BergaCare FG Olive | Hydrogenated Ethylhexyl Olivate, Hydrogenated Olive Oil Unsaponifiables | Berg+Schmidt | 10.0 |

| B | Sunflower Seed Oil | Helianthus Annuss (Sunflower) Seed Oil | Henry Lamotte | 5.0 |

| B | BergaCare FG Gel | Hydrogenated Ethylhexyl Olivate, Hydrogenated Castor Oil/Sebacic acid, Hydrogenated Olive Oil Unsaponifiables | Berg+Schmidt | 3.0 |

| B | Keltrol CG-SFT | Xanthan Gum | CP Kelco | 0.2 |

| B | Jojoba Oil | Simmondsia Chinensis (Jojoba) Seed Oil | Henry Lamotte | 8.0 |

| B | Vegarol 18-98 | Stearyl Alcohol | Berg+Schmidt | 1.0 |

| B | Cosphaderm T70 non-GMO ECO | Tocopherol, Helianthus Annuus Seed Oil | Cosphatec | 0.5 |

| C | AquaLipids Bisabolol AR | Aqua, Oryza Sativa Bran Oil, Glcerin, Cetyl Palmitate, Glyceryl Behenate, Bisabolol, Pentylene Glycol, Phytosterols, Sodiu Stearoyl Glutamate, Tocopherol, Helianthus Annuus Seed Oil | Berg+Schmidt | 3.0 |

| D | Aloe Stars | Perfume | Vögele | 0.2 |

| 100.0 |

Tab. 1. Elegant Gel-Cream for mature skin (RFGG-04.01-1223), natural o/w emulsion with particularly luxurious skin feel.

Manufacturing procedure:

- Weigh in phase A and heat up to 65°C.

- Weigh in phase B and heat up to 75°C.

- Add phase A to phase B while homogenization, homogenize for 1 min. at 9000 rpm.

- Cool down to room temperature while stirring.

- Add phase C under 40°C.

- Add phase D at room temperature.

- pH = 5.0- 5.5

Seeking new formulation concepts

The olive and castor-based oil thickener blend has already shown to be very compatible with commonly used cosmetic raw materials and helps to overcome several manufacturing challenges due to its cold processability and thickening stability also at elevated temperatures. But there is more when looking at new natural formulation types. As the thickener is compatible also with sodium cocoyl isethionate, it can carry the surfactant and create oil-gel-to-milk cleansing products. Are purely thickened oil with 5% of the thickener is a suitable formulation for hair tips fluids or body oils with a longer playtime.

A more creative and playful concept is the bouncing lip balm which can be applied on dry lips or to prepare the lips for further lipstick. The lip balm uses a higher concentration of the thickener in combination with other vegetable oils and antioxidants leading to the bouncy texture.

| Product | INCI Name | Supplier | % (w/w) |

| Jojoba Oil | Simmondsia Chinensis (Jojoba) Seed Oil | Henry Lamotte | 10.0 |

| Castor Oil | Ricinus Communis (Castor) Seed Oil | Henry Lamotte | 4.6 |

| BergaCare FG Olive | Hydrogenated Ethylhexyl Olivate, Hydrogenated Olive Oil Unsaponifiables | Berg+Schmidt | 10.0 |

| BergaCare FG Gel | Hydrogenated Ethylhexyl Olivate, Hydrogenated Castor Oil / Sebacic acid, Hydrogenated Olive Oil Unsaponifiables | Berg+Schmidt | 75.0 |

| Cosphaderm T70 non-GMO ECO | Tocopherol, Helianthus Annuus Seed Oil | Cosphatec | 0.2 |

| Honey | Aroma | OlbrichtArom | 0.2 |

| 100.0 |

Table 2. Bouncing Lip Balm (Internal Ref.: RFGG-02.01-1223), a cold-processed Jello-like Balm for dry lips.

Manufacturing procedure:

- Weigh in all raw materials.

- Mix them at 11.000 rpm for 9 min.

Conclusion

This article discusses the different possibilities of oil thickening in cold process. Formulators can already choose between a number of ingredients existing on the market for cosmetic ingredients and which generate similar results by having a different mode of action. By using the blend mixture of olive squalane, hydrogenated ethylhexyl olivate and the copolymer of hydrogenated castor oil with sebacic acid the final product will show a well-jellified, transparent oil-gel allowing for new, trending products.

[1] Steffen Praetorius, Britta Schößer: Bentonithandbuch, Ringspaltschmierung für den Rohrvortrieb, 9.

[2] Jürgen Falbe und Manfred Regitz: RÖMPP Chemie Lexikon , H-L, 1750.

[3] Fraunhofer Institut: www.umsicht.frauenhofer.de, Grundlagen zu Polymeren und Kunststoff.

Share this article

Back to News