Broadening the choice of natural emulsifiers by using synergistic fiber blends

Kristin Köhler – Berg+Schmidt

Introduction

To develop natural cosmetic emulsion products, formulators can choose from a broad range of emulsifiers. The existing emulsifiers are well-known to the market, are usually easily available and offer typical textures and sensory consumers and formulators are equally used to. However, most of them are only hot-processible, tend to soap, are esterified, and may lead to a relative waxy skin after feel. Fiber-based emulsifiers are cold-processible, which can lead to reduced process time and energy costs. The desired galenic can be varied in its viscosities e.g., from gels to creams as well as in their appearance and skin feel. Depending on the composition, fiber blends can benefit from complementary functionality of soluble and insoluble fiber compounds used.

Fibers from agro-food industries

Dietary fibers result from extracting waste from food processing industries and can be divided into soluble and insoluble fibers originating from fruit or vegetable sources e.g., apples, root legumes, whole grains, and bran.[1] Upcycled and water-soluble fibers are being re-used at their source for many years as carbohydrate polymers i.e., hydrocolloids to enhance product stability and shelf life and to act as stabilizing gelling agents in e.g. soups or dressings. Typical examples in cosmetic applications are pectin or gums e.g., from guar or locust beans.

Pickering emulsions

In contrast to hydrocolloids, the insoluble fibers are of main interest for the formation of pickering emulsions, which use a different technique to form emulsions. Instead of traditional surface-active emulsifiers, solid particles are responsible for stabilizing the oil-water interface to prevent from coalescence. Solid particles can be of organic or inorganic origin like titanium dioxide, clay or: fibers. Insoluble fibers can be glucans from cereal bran or other glucose monomers. Not all fibers show the same behavior in formulated products. Especially the solid fibers require more screening work to find suitable components. Particle wettability, oil-water phase ratio, adsorption of the solid particles at the interface and the surface coverage by particles are decisive aspects to identify suitable insoluble fibers.[2]

Selection of fibers

Knowing about the different characteristics of soluble and insoluble dietary fibers, their combination leads to a synergistic mode of action, where the insoluble fibers create pickering emulsion and the water-soluble components support emulsion stability by building a surrounding hydrocolloidal network. For the development of a synergistic fiber blend, the following criteria were set among others: It should stabilize emulsions of about 20% w/w of oil, o/w emulsions should be cold-processible, stability without high sheer rates and stable at 40°C for min. 3 months.

The screening of a total of 42 potentially suitable fibers comprised various tests e.g.:

- Visual inspection and gel-forming ability

- Particle size distribution and particle size.

- Oil and water holding capacity.

- Ability to form emulsions.

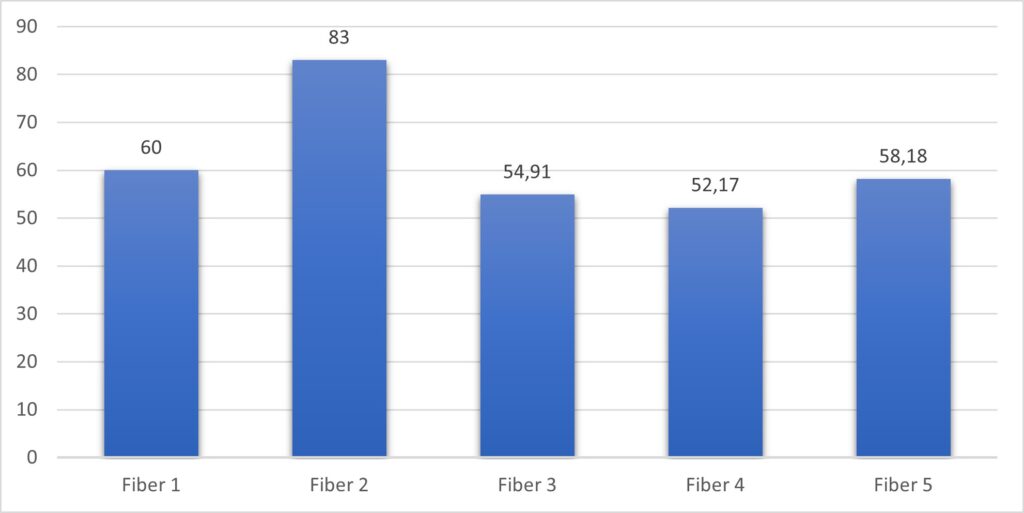

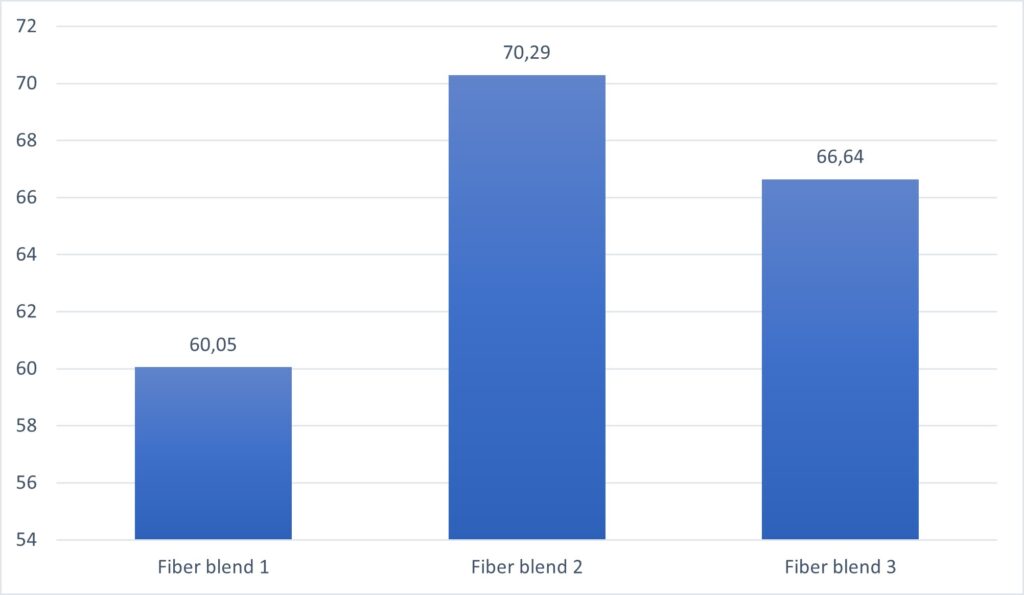

- Contact angle measurement.

The contact angle measurement is an important part of the overall analysis. Particles for pickering stabilization should exhibit hydrophilic and hydrophobic properties. The ideal contact angle is close to 90° i.e. slightly below 90° for o/w emulsions (particles are mainly wetted by the water phase) and slightly above for w/o emulsions.

Based on the findings of the contact angle measurement, we can assume that the wetting ability changes when the fibers are mixed. At the end of the screening process, the following fibers were identified to work as an efficient and cold-processible compound as requested and exhibiting further important cosmetic functions:

- Oat fiber, known for its soothing and moisturizing properties, contains beta-glucans, which have excellent water-holding properties, contributing to improved hydration and skin barrier support.

- Guar Gum, a botanical ingredient derived from guar beans, has long been used in various industries for its thickening and stabilizing properties. In cosmetic formulations, guar gum plays a key role in improving the texture and viscosity of emulsions, ensuring smooth and appealing product application.

- Wood fiber, derived from sustainable sources, brings inherent benefits to the cosmetic formulation. Its microstructure and hydrophilic nature allow it to efficiently stabilize the oil and water phases, facilitating the formation of stable emulsions.

Not every dietary fiber is suitable for usage in cosmetic formulations. Some are failing simply due to its color, do not present a pleasant texture or have no thickening or emulsifying properties.

in the fiber blend

Formulating the product

The texture of cosmetic emulsions plays an important role in enhancing the user experience and product effectiveness. By varying the concentration of the oil phase, a wide range of textures can be achieved. The typical texture is obtained with the formulation example shown in the table.

| Phase | Product | INCI Name | Supplier | % (w/w) |

| A | Demin.Water | Aqua | - | 80.4 |

| A | Cosphaderm Dicapo Natural | Caprylyl Glycol (and) Propanediol (and) Glyceryl Caprylate | Cosphatec | 1.0 |

| A | Cosphaderm Pentiol Natural | Pentylene Glycol | Cosphatec | 2.0 |

| A | Rice PO4 Natural | Distarch Phosphate | Agrana | 1.5 |

| A | Glycerin 99.5% | Glycerin | Berg+Schmidt | 3.0 |

| B | BergaCare FG M12 | Coco-Caprylate/Caprate (and) Dodecane (and) Citrullus Lanatus (Watermelon) Seed Oil | Berg+Schmidt | 2.0 |

| B | BergaMuls ET 2 | Cellulose (and) Cyamopsis Tetragonoloba (Guar) Gum (and) Beta-Glucan | Berg+Schmidt | 1.5 |

| B | Grape Seed Oil | XaVitis Vinifera Seed Oil | Henry Lamotte | 5.0 |

| B | Hazelnut Oil | Corylus Avellana Seed Oil | Henry Lamotte | 3.0 |

| B | Keltrol CG-SFT | Xanthan Gum | CP Kelco | 0.1 |

| B | Cosphaderm T70 non-GMO ECO | Tocopherol, Helianthus Annuus Seed Oil | Cosphatec | 0.5 |

| B1 | Perfume | Aloe Stars | Vögele | 0.1 |

| C | Citric Acid (25% solution.) | Cirtric Acid | Diverse | Adjust pH |

| 100.0 |

Conclusion

With consumers becoming more and more interested in natural and upcycled products, formulators are well-advised to consider working with fiber-based emulsifier blends to take advantage of the easy processing and synergistic mode of action leading to stable o/w emulsions with modern sensory.

[1] Hussain, S.; Jõudu, I.; Bhat, R.: Dietary Fiber from Underutilized Plant Resources—A Positive Approach for Valorization of Fruit and Vegetable Wastes. Sustainability 2020, 12, 5401.

[2] Berg + Schmidt GmbH & Co KG, unpublished dissertation results of 2022

Share this article

Back to News