Emulsions Without Emulsifiers – Synergistic Plant Fibers in Cosmetic Textures

Dr. Sabilla Digel

Introduction

Emulsions are everywhere in daily life, and serve as a base technology for products in the food, cosmetics, and pharmaceutical industries. Whether in creams, lotions, sauces, or drug delivery systems, the stabilization of emulsions is traditionally ensured with the aid of surface-active molecules or polymers to prevent coalescence of the droplets. However, growing consumer demand for sustainable, natural, and skin-friendly alternatives has led to the development of innovative emulsion stabilizers. One such approach is the use of Pickering emulsions—emulsions stabilized by solid particles that adsorb irreversibly at the oil-water interface.

Pickering emulsions were first described in the early 20th century by W. Ramsden[1] and S.U. Pickering[2] (1903 and 1907 respectively), and their practical applications are still numerous today. While in conventional emulsions surface-active molecular emulsifiers orient themselves at the water-oil interface depending on their lipophilic and hydrophilic moieties, Pickering emulsions are stabilized by solid particles that adsorb irreversibly at the oil-water interface, creating a physical barrier to droplet coalescence. These emulsions are known for their exceptional stability[3], good skin compatibility, and ability to provide sophisticated and appealing sensorial properties on the skin. A promising approach to Pickering emulsifiers exploits the potential of using fibers and hydrocolloids that are widely used in the food industry, as their unique properties can be exploited to solve challenges in cosmetic applications, and to create innovative textures while improving environmental sustainability.

This article describes our research on developing plant fiber-based materials for the stabilization of Pickering emulsions in cosmetic applications by combining the synergistic properties of fibers and hydrocolloids. In the following sections we detail the design, characterization, and application of these plant fiber-derived materials, demonstrating their effectiveness in stabilizing emulsions while meeting the increasing demands for sustainability and performance in the modern cosmetic industry.

Synergistic Plant Fibers Open Doors to Different Textures

The journey toward creating innovative fiber-based emulsifying agents for cosmetic applications begins with an understanding of the wide selection of available plant fibers. In an extensive examination of raw materials from different plant sources, we assessed their suitability to stabilize emulsions, first individually and then in the form of fiber mixtures.

Key Considerations in Fiber Selection

In the screening process, we addressed a variety of critical factors to identify plant fibers that meet the high standards of cosmetic formulations:

- Sensory Properties: Fibers with undesirable characteristics, such as visible color or particles that can be perceived when distributed on the skin, were excluded early in the selection process.

- Emulsion Stabilization: The fibers’ ability to stabilize O/W emulsions under common shear rates was tested.

- Thickening and Gelling: Beyond emulsification, many fibers are able to thicken or gel the water phase, contributing further to stabilizing cosmetic emulsions.

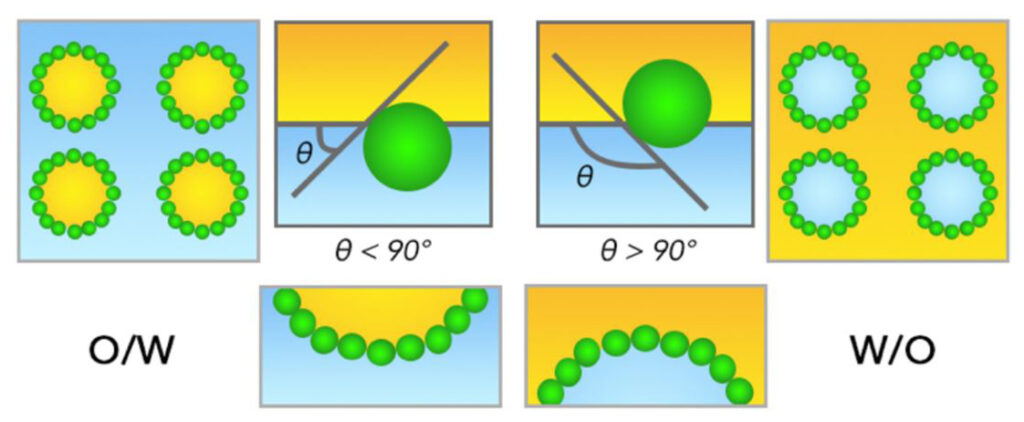

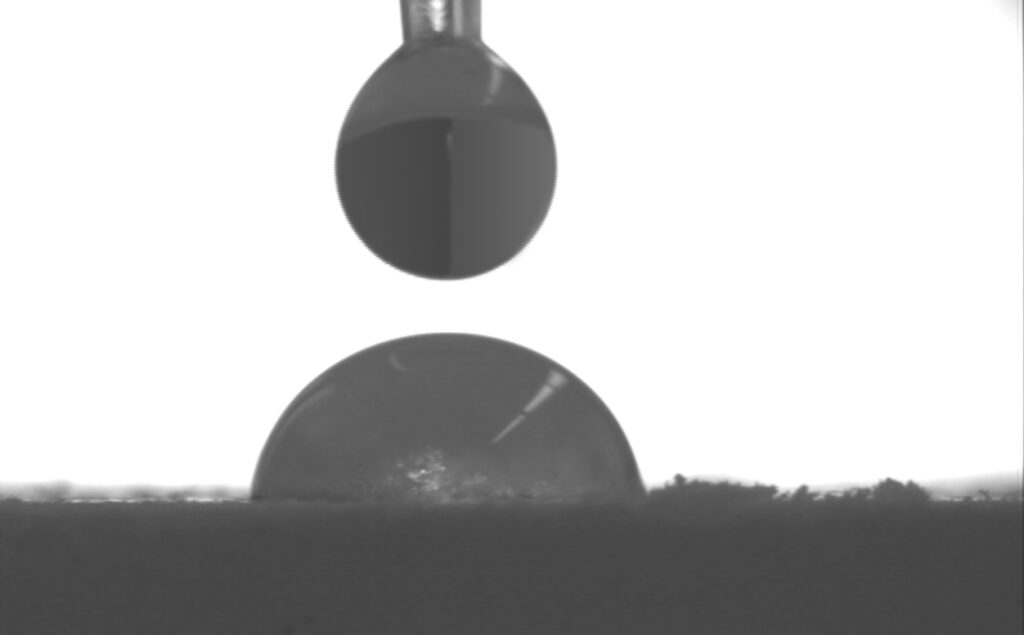

- Surface Properties: The hydrophilic and hydrophobic balance of fibers, characterized by contact angle measurements using the sessile drop method. The contact angle θ indicates how the solid particle wets the oil and water phases. At θ < 90° the particle is more hydrophilic and prefers the water phase. At θ > 90° it is more lipophilic and prefers the oil phase. If θ is < 90° but close to 90°, the particle is amphiphilic, having the ideal properties to stabilize O/W emulsions [Figure 1].[4]

- Formulation Stability: The resulting formulations were subjected to standard storage conditions (40 °C for 12 weeks) to evaluate stability over time.

- Practical and Regulatory Aspects: Factors such as affordability, availability, geographic origin, quality reliability, and compliance with cosmetic regulations were also considered in the process.

Our evaluation ultimately led to the development of two synergistic fiber blends, BergaMuls ET1 (consisting of beta-glucan and pectin) and BergaMuls ET2 (consisting of cellulose, guar, and beta-glucan). The "ET" in their names stands for "Emulsifying & Thickening," emphasizing their dual functionality. These blends are both derived 100% from plants, and are complementary regarding the accessible cosmetic textures, offering versatility to formulators.

Comparison of the two fiber blends

While both blends share a multitude of advantages, they still exhibit distinct properties in formulations. A summary is shown in Table 1.

Table 1. Comparison of the two fiber-based blends.

| Product | BergaMuls ET1 | BergaMuls ET2 |

| INCI | Beta-Glucan, Pectin | Cellulose, Cyamopsis Tetragonoloba (Guar) Gum, Beta-Glucan |

| Source | Cereal fiber, fruit fiber | Wood fiber, guar gum, cereal fiber |

| Appearance | Ivory-colored powder | White to off-white powder |

| COSMOS | Approved | Approval pending |

| ISO 16128 | Ino = 1 | Ino = 1 |

| Use concentration | <2% as co-emulsifier 2-3% as main emulsifier >3% as single emulsifier | 1.5-2% as main emulsifier |

| Additional functions | Sensory enhancer Thickener | Sensory enhancer Thickener |

| Process temperature | Hot or cold | Hot or cold |

| Accessible textures | Lotion-like textures | Cream-gel textures of various viscosities |

| pH range of final formulation | 4-9 | 4-9 |

Both fiber blends are from 100% natural / renewable resources and allow the production of COSMOS-certified cosmetics. They serve as emulsion stabilizers, sensory enhancers, and thickeners, and are produced in Germany. Furthermore, they are both hot- and cold-processable without impacting the final viscosity, giving flexibility during production. They are very skin-friendly as they do not exhibit any surface activity. Therefore, they are ideal for the design of emulsifier-free concepts. Finally, stable emulsions can be achieved across a wide range of pH 4-9.

What makes the two blends different from each other is the accessible textures. While BergaMuls ET1 is the ideal choice for creamy, lotion-like textures, BergaMuls ET2 can be used to access shiny, cream-gel textures with a hint of freshness in various viscosities from serum to cream.

Know Your Pickering Emulsifier: General Formulation and Application Advice

The emulsion stabilizers presented differ not only in their resulting textures, but also in the production parameters in which they give the best performance. With the following points taken into consideration, the two blends give additional flexibility depending on the available equipment and production conditions.

- Dispersing the Product: Both blends should be dispersed in the oil phase prior to the emulsification step, as this allows for quicker homogeneous distribution.

- Emulsification Process: While the blend based on beta-glucan and pectin gives the best results (in terms of viscosity and long-term stability) when homogenized for a short time (7000-9500 rpm for 30-60 seconds), the blend based on cellulose, guar, and beta-glucan works best when using low shear rates for a prolonged time (propeller stirrer at 1500-1900 rpm for 10-20 min), as the fiber mix needs to be given sufficient time to orient itself at the oil-water interface and for the hydrocolloids and soluble fibers to swell in the water phase.

- Thickening Options: Use 4% of fibre mix 1 in water-based (oil-free) formulations to create a semitransparent gel. The viscosity at 3% differs significantly between the two (1340 mPas for fibre mix 1 vs. 14800 mPas for fibre mix 2).

- Preservation Options: Formulations can be preserved with natural antimicrobials using 5% pentylene glycol or a combination of 2% pentylene glycol with 1% Cosphaderm® Dicapo Natural (caprylyl glycol, propanediol, glyceryl caprylate).

Table 2. Comprehensive summary of application advice.

| INCI | Beta-Glucan, Pectin | Cellulose, Cyamopsis Tetragonoloba (Guar) Gum, Beta-Glucan |

| Dispersion phase | Oil phase | Oil phase |

| Recommended process for best stability and viscosity | Short homogenization (Ultra Turrax, 7000-9500 rpm, 30-60 seconds) | Stirring at 1500-1900 rpm for 10-20 min |

| Appearance in formulation | Off-white in water and emulsions | Significantly whiter in water and emulsions |

| Sensory and texture | Creamy, silky, caring, slightly less shiny surface, texture can be enhanced with fatty alcohols | Cream-gel texture, shinier surface, texture can be enhanced with fatty alcohols |

| Oil compatibility | Compatible with all oil polarities | Not compatible with silicone oils or high amounts of alkanes; works well with esters and best with plant oils |

| Recommended use levels | <2% as co-emulsifier; 2-3% as main emulsifier; >3% as single emulsifier | 1.5-2% as main emulsifier Exceeding 3% can lead to very high viscosities, making thorough mixing difficult Stability can be further boosted with gelling agents like xanthan gum (0.05%) or konjac (0.2%) |

| Size of oil phase | 8%-50% | 10%-30% |

| Use as a thickener | 4% in water-based (oil-free) formulations to create a semi-transparent gel | 3% in water leads to excellent viscosity build-up of 14.800 mPas |

| Use as sensory enhancer | 2% in addition to classical emulsifier system | To be explored |

| Preservative systems with confirmed passed challenge test | 5% pentylene glycol | 5% pentylene glycol Or 2% pentylene glycol + 1% Cosphaderm® Dicapo Natural (caprylyl glycol, propanediol, glyceryl caprylate) |

Versatile Formulation Concepts With Fiber-Based Pickering Emulsifiers

The following section exemplifies the potential of plant-based emulsifiers to create versatile and sustainable formulations for the cosmetic industry. Formulators can achieve a variety of textures, from light lotions to rich creams, in cold or hot process, with or without co-emulsifiers.

Formulating with BergaMuls ET1

Light Zen Milk

Emulsifier-free, silky and smooth, soothing formulation which is gentle to the skin barrier. The fiber blend (2% use level) acts as a single emulsifier, stabilizing the 8% oil phase with 0.1% xanthan gum as additional stabilizing aid. See the formulation here: Light Zen Milk

Silky Underwear

This smooth, powdery and gliding texture exhibits a mattifying effect thanks to 2% fiber blend, which acts primarily as a sensory enhancer in this example. See the formulation here: Silky Underwear

Quench Your Thirst Cream-In-Serum

A water-based / oil-free serum that has the appearance of a cream, but with the sensory properties of a serum targeting very dry skin. Here, 4% fiber blend acts as a thickener for the water phase. See the formulation here: Quench Your Thirst Cream-In-Serum

Formulating with BergaMuls ET2

Hydra-Silk Gel Elixir

This cold-processed, velvety serum uses 1.5% fiber blend together with 0.1% xanthan gum to stabilize this O/W emulsion without the need for heating. The formulation achieves a smooth, lightweight texture. Distarch phosphate contributes to the velvety sensory, but does not play a role in stabilizing the emulsion. See the formulation here: Hydra-Silk Gel Elixier

Standard Lotion

Another cold-processed formulation, this lotion demonstrates the fiber blend's effectiveness as an emulsifier-free stabilizer. By combining it with natural oils and 0.2% additional gelling agent (konjac root extract), the formulation achieves a balanced viscosity. The result is a lightweight lotion that is suitable for daily use in skincare routines. See the formulation here: Standard Lotion

Body Cream

Designed as a protective cream, this formulation uses the fiber blend as the main emulsion stabilizer along with a co-emulsifier (GSC). The result is a rich, nourishing texture ideal for dry or mature skin. See the formulation here: Body Cream

Conclusion

By combining the intrinsic properties of plant fibers with the synergistic benefits of hydrocolloids, we have unlocked new opportunities to create various textures in cosmetic formulations. The range of upcycled plant-based emulsifiers can bridge the gap between performance, sustainability, and versatility. By enabling cold processing, and aligning with natural and eco-friendly trends, it offers formulators an innovative tool to meet the evolving demands of the cosmetics market.

References

[1] Ramsden, W (1903). "Separation of Solids in the Surface-layers of Solutions and 'Suspensions'". Proceedings of the Royal Society of London. 72 (477–486): 156–164. doi:10.1098/rspl.1903.0034

[2] Pickering, Spencer Umfreville (1907). "Emulsions". Journal of the Chemical Society, Transactions. 91: 2001–2021. doi:10.1039/CT9079102001.

[3] Binks, B. P. (2002). Particles as surfactants—similarities and differences. Current Opinion in Colloid & Interface Science, 7(1-2), 21-41.

[4] Velikov, Krassimir P.; Velev, Orlin D. (2014). Colloid Stability. pp. 277–306. doi:10.1002/9783527631193.ch35. ISBN 9783527631193.

Matching Products

Share this article

Back to News